Super Purchasing for Laminate safety glass - Ionoplast interlayer film – Xiaoshi

Super Purchasing for Laminate safety glass - Ionoplast interlayer film – Xiaoshi Detail:

Ionoplast interlayr film technology breaks the foreign monopoly of high strength ionoplast interlayer material for laminated safety glass, and promoting the development of the whole laminated glass industry.

It is made of ethylene and methacrylate ion copolymer, containing about 1% metallic sodium ion. Five times stronger and up to 100 times stiffer than conventional laminating materials. With this kind of strength the glass can be a more active structural element in the constructions, opening up design possibilities that didn’t exist before. Besides its strength, the ionoplast interlayer retains excellent optical and visual performance even after years of outdoor exposure. Ionoplast interlayer film is much less vulnerable to moisture exposure or yellowing over time. It is the research achievements to meet the growing market demand for security, safety, durability, aesthetics, edge stability and other aspects of laminated glass, especially in the application like hurricane glazing, glass bridge, facades, overhead glazing ,etc.

Features

• Stiffness: 100 times stiffer of conventional interlayer materials

• Tearing strength: 5 times stronger of conventional interlayer materials

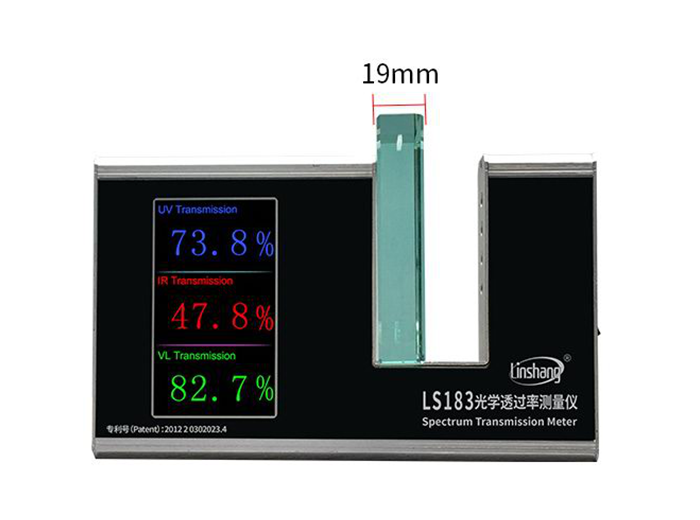

• Excellent optical and visual performance

• Yellowish index(YI): <1.5

• Outstanding durability after UV radiation

• High edge stability, Good compatibility with silicon.

Product advantages

1. Tearing strength : 5 times stronger than conventional interlayer material .

2. Stiffness: 100 times stiffer than conventional interlayer material.

3. The load-bearing of laminated glass made from Ionoplast interlayer film is twice stronger than made from PVB interlayer at same thickness combination.

4. The deflection of laminated glass made fromIonoplast interlayer film is only 1/4 of laminated glass made from PVB under the same thickness and load.

5. The stress and deflection of laminated glass made from Ionoplast interlayer film are essentially same as monolithic glass at same thickness, while the laminated glass made from PVB are much greater.

6. Reduction of glass thickness, and the glass weight could be reduced by 40%.

7. Suitable for open edge development and design.

8. Reduction the number of fixing points for frameless glazing , make design more innovative and diversification .

Storage conditions

Ionoplast interlayer film should be stored at room temperature with original sealing vacuum moistureproof packing. It is recommended use material within 24months from the date of production to avoid the decline of adhesion. Please properly seal and pack unused materials and store them in cool place to prevent the material from being exposed to the environment and absorbing moisture, which may resulting in adhesion reduced.Control the moisture of material not over 0.2%, Otherwise the adhesion may go down and have bubbles during laminating. It is also recommended that testing the moisture content and the adhesion property of Ionoplast interlayer film before production if it has been stored for a long time from the production date. If the moisture content exceeds 0.2%, it is not recommended to use.

Technical Data

| Item | Test Method | Safeglas ™ MG | |

| Physicial | Roll Length | 50-100 m | |

| Max.Width | 2400 mm | ||

| Thickness | Micrometer | 0.76-1.52 mm | |

| Specific Gravity | ASTM792 | 0.93-0.98 g/cm3 | |

| Hardness(1.52mm) | ASTMD2240 | 65 Shore D | |

| Mechanical | Elongation at Break | ASTMD683 | ≧ 300% |

| Young modulus | ASTMD683 | >300 Mpa | |

| Shear modulus | ASTMD683 | 42.7 N/mm2 | |

| Bending modulus | ASTMD683 | 345 Mpa(23 ℃) | |

| Shear strength | ASTMD683 | 50 MJ/m2 | |

| Tensile strength | ASTMD683 | ≧ 30 Mpa | |

| Thermal | Coeffcient of thermal expansion | ASTMD831 | 10-15*103cm/cm ℃ |

| Thermal deflection temperature | ASTMD831 | 40 ℃ | |

| Melt point | ASTMD831 | 94 ℃ | |

| Flash point | ADTMD1929 | 470 ℃ | |

| Optical | YI | JC/T2166-2013 | <15% |

| Refractive Index | JC/T2166-2013 | 1.5%(20 ℃) | |

| Light Transmittance | JC/T2166-2013 | 90.2 % (0.76mm) | |

| Haza | JC/T2166-2013 | <0.5 % (0.76mm) | |

| UV filtering | JC/T2166-2013 | >99 % (380nm) |

Product Specifications

| Thickness (mm) | Max.Width (mm) | Length(m) | Packing |

| 0.76/0.89/1.14 | 2400 | 100 | Inside: Tinfoil vacuum Outside: Plywood case |

| 1.35 | |||

| 1.52 | 50 | ||

| Application: Facades, Hurrican Glazing, Sunroom Glazing, Jumbo Glass, etc. | |||

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Super Purchasing for Laminate safety glass - Ionoplast interlayer film – Xiaoshi , The product will supply to all over the world, such as: Anguilla, Qatar, Jeddah, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.