Short Lead Time for Eva Lamination - Intelligent Insulating Glass Inflator – Xiaoshi

Short Lead Time for Eva Lamination - Intelligent Insulating Glass Inflator – Xiaoshi Detail:

Advantages

1. First of all, in the increasingly competitive insulating glass market, filling inert gas can not only increase the performance of insulating glass, but also increase the selling point of the product and become a new marketing tool.

2. After inflation, the internal and external pressure difference can be reduced, the pressure balance can be maintained, and the glass explosion caused by the pressure difference can be reduced.

3. After filling with argon gas, it can effectively improve the K value of the insulating glass, reduce the condensation on the indoor side glass, and improve the comfort level, that is, the inflated insulating glass is less prone to condensation and frost.

4. Due to the characteristics of argon as an inert gas, it can slow down the heat convection in the insulating glass, and at the same time, it can greatly improve its sound insulation and noise reduction effect, that is, the insulation and sound insulation effects of the insulating glass can be better.

5. It can increase the strength of large-area insulating glass so that its middle part does not collapse.

6. Increase wind pressure strength.

7. Because the filled gas is dry and inert gas, the moisture-laden air in the hollow glass cavity can be replaced to keep the environment inside the cavity dry and prolong the life of the molecular sieve in the aluminum spacer frame.

8. When using low-emission LOW-E glass or coated glass, because the gas filled is an inactive and inert gas, it can protect the film layer to reduce the oxidation rate and prolong the service life of the coated glass.

Characteristics

1. Two inflation modes: (1) Manual control mode: You can control the inflation process through the “Start” and “Stop” buttons. (2) Automatic control mode: The concentration of the aerated body is automatically detected by the control system, and it stops automatically when it is full.

2. High working efficiency: four pieces of insulating glass can be filled at one time.

3. Adjustable parameters: the inflation concentration can be set by itself, which is convenient and flexible.

4. The whole work process has indicator light display, the working status is intuitive, and it is convenient for the operator to monitor.

5, simple operation: simple operation, no training, no matter what kind of inflation, just press the “start”, “stop” button to complete the entire operation.

6. The equipment is controlled by the imported controller. The control system is stable and has a long service life.

7. The control elements of the detection part of the equipment are imported from the United Kingdom, with high accuracy and stable performance.

8. The device is portable, small in size, light in weight, easy to transport and install, and more convenient to operate on site.

9. The inflation method is novel, does not damage the appearance of the aluminum spacer, and maintains the overall appearance of high-quality insulating glass.

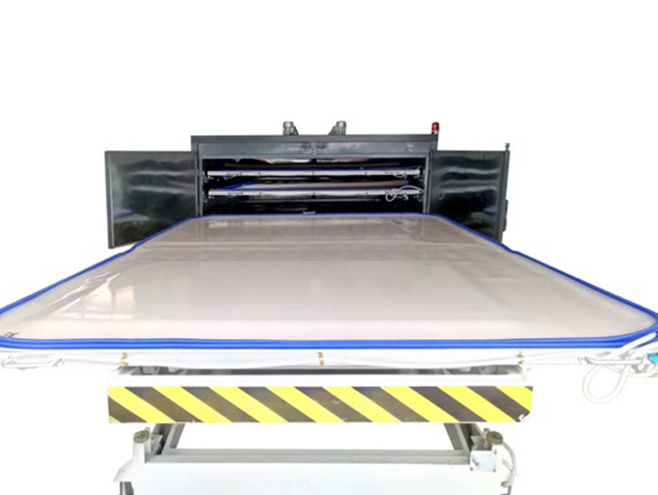

10. Please refer to the following figure for the appearance effect diagram (if there is any change in appearance in the production process without notice, the actual product shall prevail)

The electrical components are Shanghai thin, the pneumatic components are SMEG, the sensors are British CITY, the control part is developed by our company’s patents, and all the air pipes are imported

Technical parameters:

1. Argon gas source: pressure 0.1Mpa, flow rate 0.01L / min.

2. Operating environment: 0 ~ 40 ° C, no condensation, operation panel and electric control box should not be immersed in sleep.

3. Voltage: AC220V or customized

4. Power: 100W

Product detail pictures:

Related Product Guide:

With our superb management, potent technical capability and strict quality command procedure, we go on to provide our shoppers with trustworthy high-quality, reasonable costs and outstanding services. We goal at becoming considered one of your most trustworthy partners and earning your pleasure for Short Lead Time for Eva Lamination - Intelligent Insulating Glass Inflator – Xiaoshi , The product will supply to all over the world, such as: Slovakia, Malaysia, Chile, To work with an excellent items manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.