In the automotive industry, safety and durability are paramount, particularly when it comes to vehicle glass. This is where PVB films, an advanced solution for automotive glass safety, come into play. With their unique structure and exceptional bonding properties, PVB films offer a robust solution for enhancing impact resistance and clarity in automotive glass, making them ideal for manufacturers and repair experts focused on delivering safer vehicles.

PVB film is interlayer materials designed to be sandwiched between layers of glass, offering strength, durability, and high clarity. PVB films are engineered to withstand extreme forces, providing extra security and enhancing visibility even in adverse conditions. This makes them ideal for vehicles exposed to varying environmental challenges and potential impact scenarios.

Benefits of PVB Film for Automotive Glass

1,Enhanced Impact Resistance: PVB film for automotive glass provides unparalleled impact resistance, making it a preferred choice for car windows and windshields. This material can absorb and distribute energy from collisions, reducing the likelihood of shattering. This is essential for keeping occupants safe in case of accidents, and it contributes to structural integrity by preventing glass from scattering.

2, High Optical Clarity: Maintaining visibility is crucial for drivers. PVB film is engineered for high optical clarity, providing a clear, distortion-free view through automotive glass. This is particularly valuable for manufacturers aiming to enhance driver safety, as a clear windshield or window can make a significant difference in reaction times and overall driving experience.

Real-World Applications and Advantages for Automotive Repair and Manufacturing In practice, PVB films allow automotive repair professionals to provide reliable solutions for glass replacement, particularly in vehicles where safety is prioritized. From passenger vehicles to specialized fleet vehicles, the adoption of PVB film for automotive glass is a proactive choice that improves overall durability and security. This solution is especially appealing for electric vehicle manufacturers and eco-conscious consumers who value safety innovations that add efficiency.

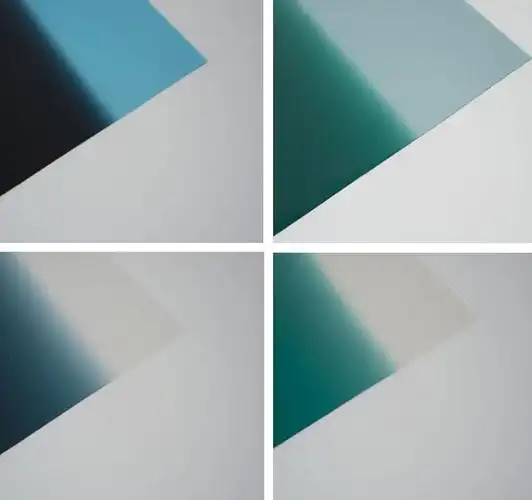

3,UV block Character: Automotive-grade PVB film has the function of blocking ultraviolet rays. Its blue and green bands can effectively prevent the strong light of ultraviolet radiation from irradiating the driver and reduce the occurrence of traffic accidents. At the same time, due to its poor thermal conductivity, it is more comfortable than the front windshield of the vehicle without PVB interlayer, which can save the energy consumption of the car air conditioner and avoid the inconvenience of the driver after being exposed to the sun for a long time.

As a high-performance, dependable interlayer solution, PVB film is a pivotal choice in automotive glass safety, setting a new standard in impact resistance, clarity, and durability. For those in automotive manufacturing or repair, incorporating PVB film in vehicle glass applications not only improves safety but also demonstrates a commitment to cutting-edge safety standards.

With the continuous development of the automotive industry, the application of automotive-grade PVB film is becoming more and more extensive. It is not only used for front windshields, but is also increasingly used to make side panels and roof glass for luxury cars to improve safety and reduce noise and light exposure.

Post time: Nov-18-2024