As the preferred interlayer for decorative glass lamination, colored EVA film has advantages in four dimensions: color expression, process adaptability, performance stability and cost-effectiveness. The following is a specific analysis:

1. Color expression: rich and lasting

The core advantage of colored EVA film lies in its rich color selection and excellent weather resistance.

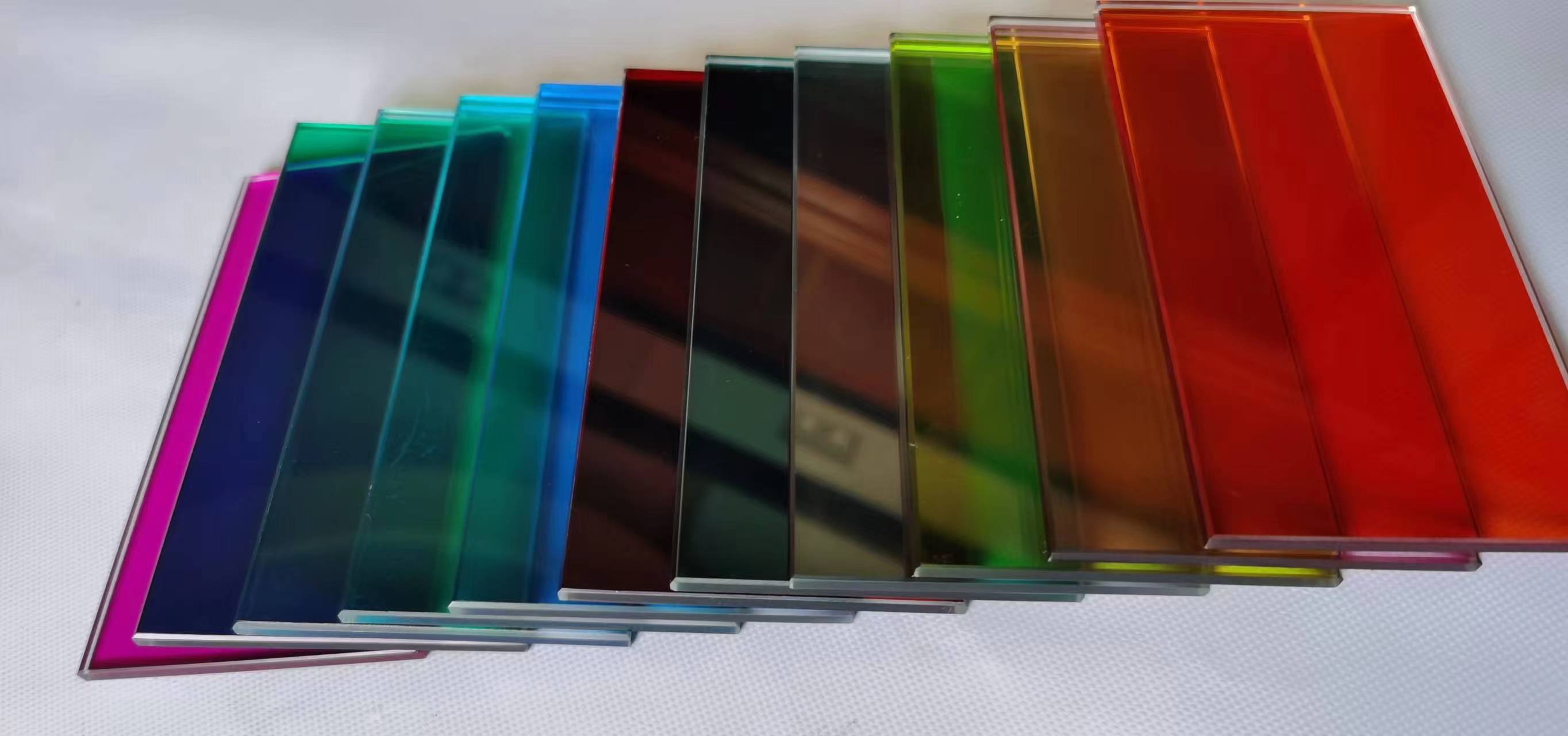

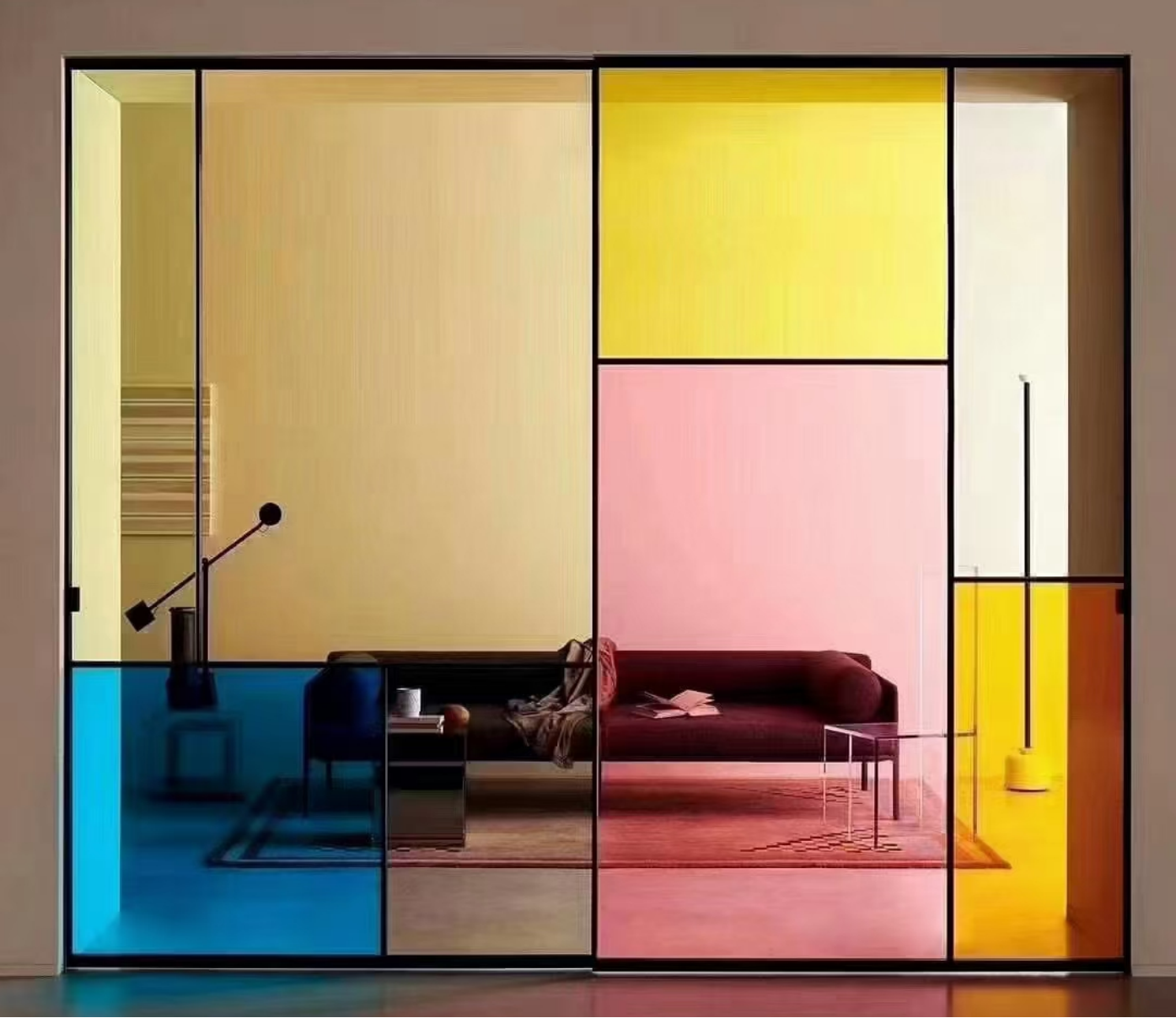

·Color diversity: EVA film can be customized in a variety of colors by adding different masterbatches, including transparent, translucent, solid colors, etc., to meet the decoration needs of different scenes such as building curtain walls, interior partitions, and art installations.

·UV and yellowing resistance: High-quality EVA film is specially formulated and optimized to effectively resist ultraviolet radiation. It is not easy to fade or yellow after long-term use. It is especially suitable for outdoor decoration scenes (such as glass curtain walls and awnings) to ensure the durability of the decorative effect.

2. Process adaptability: easy and flexible operation

Colored EVA film shows extremely high process compatibility during processing and can adapt to a variety of glass types and production methods.

· Low processing temperature: The melting temperature of EVA film is usually between 100-120℃, which is significantly lower than that of PVB film (130-150℃), which can reduce the risk of deformation of glass at high temperatures and is especially suitable for lamination of thin glass or special-shaped glass.

Low equipment requirements: No complex equipment such as autoclaves is required, and ordinary laminated glass production lines can complete the processing, reducing production costs. For example, in small and medium-sized glass processing plants, the investment cost of a production line using EVA film is only 60%-70% of that of a PVB film production line.

·High degree of freedom in interlayer design: EVA film has good fluidity in the molten state, and can realize composite processes such as wire interlayer, silk interlayer, and film interlayer, providing more design possibilities for decorative glass. For example, in indoor partitions, a unique texture effect can be formed by embedding metal mesh or fabric in EVA film.

3. Performance stability: safe and practical

Colored EVA film can not only meet the needs of decoration, but also provide reliable safety performance and practicality.

· Impact resistance: In the impact resistance test, EVA laminated glass can withstand the impact of a 5kg steel ball falling from a height of 1.2m without breaking, ensuring safe use.

· Heat insulation performance: By adjusting the thickness and formula of the EVA film, the heat insulation effect of the glass can be improved.

· Moisture resistance and weather resistance: EVA film is not prone to delamination or bubbles in a humid environment, and has strong adaptability to temperature changes, suitable for applications under different climatic conditions.

4. Cost-effectiveness: A cost-effective choice

Colored EVA film has significant cost advantages while ensuring performance.

· Low material cost: The raw material cost of EVA film is about 20%-30% lower than that of PVB film, and the loss rate during processing is lower (EVA film loss rate is usually ≤3%, PVB film loss rate is about 5%-8%).

· High production efficiency: Due to the low processing temperature and simple process, the production cycle of EVA film can be shortened by about 30%, further improving production efficiency.

· Low maintenance cost: The service life of EVA laminated glass is more than 15 years, and no special maintenance is required, which can significantly reduce the cost of use in the long run.

Post time: Apr-28-2025