Newly Arrival Glass lamination process - White EVA film – Xiaoshi

Newly Arrival Glass lamination process - White EVA film – Xiaoshi Detail:

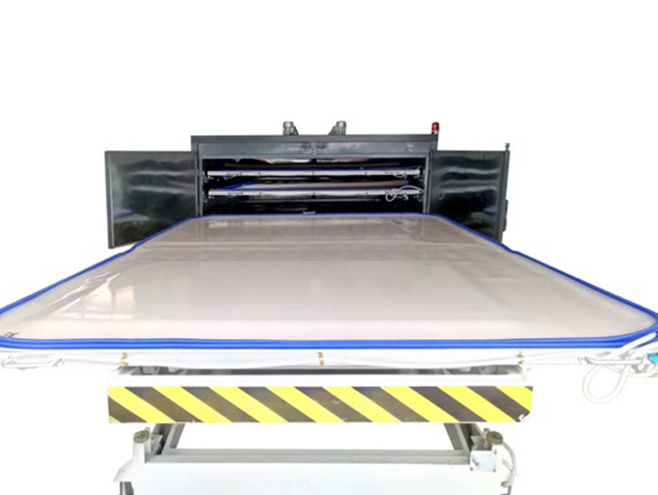

Laminated glass EVA film is placed between two layers of glass, a continuous vacuum is requested to pump out air when heated up to soften the film and laminate 2 pcs of glass into safety glass.

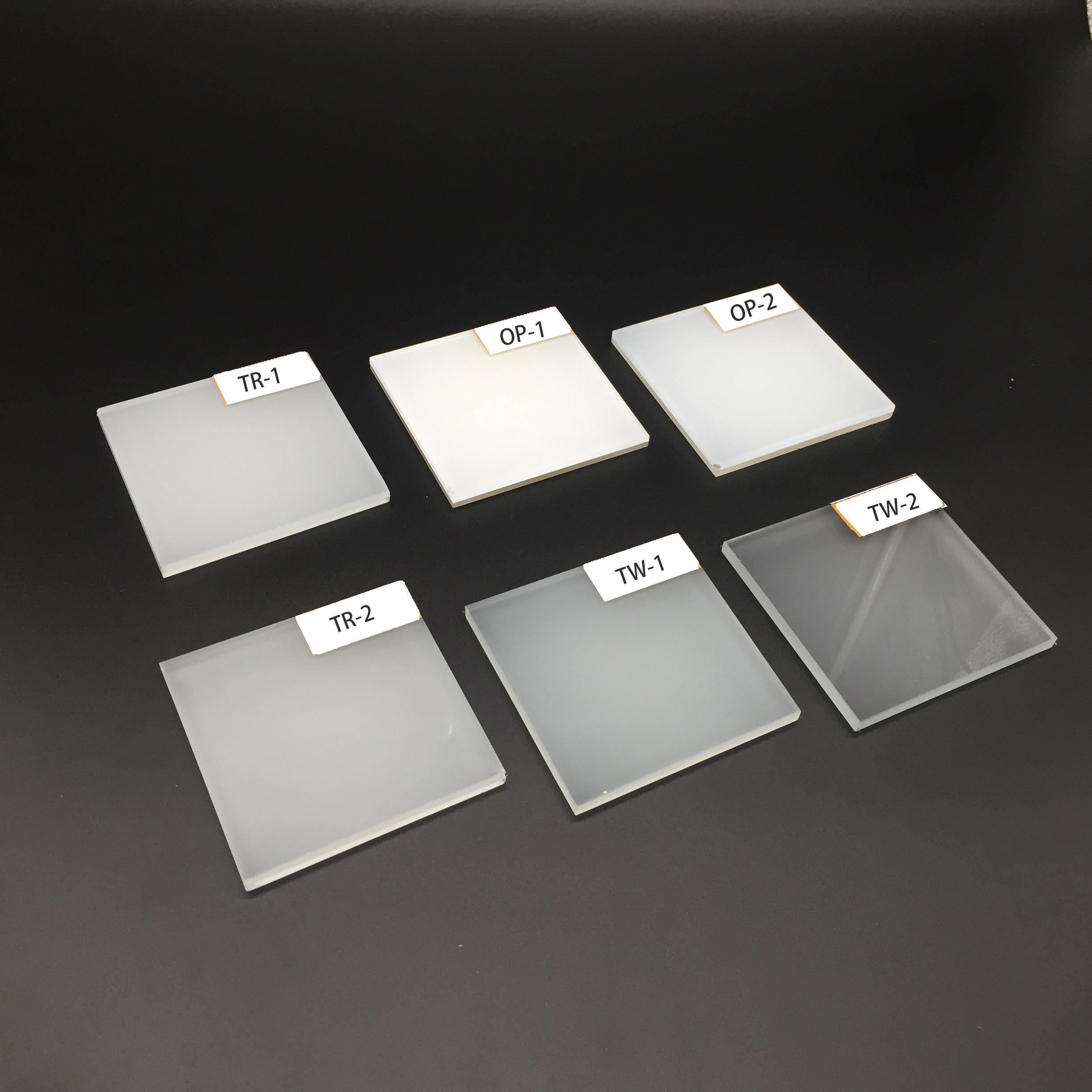

There are different types of white EVA film for safety glass lamination.

White opaque, Super white, Frosted white, Milky white and Jade white.

White color EVA film can be used for both indoor and outdoor glass lamination and also insert materials lamination. It has lower lamination temperature which are suitable for match with different types of inserts( Fabric, PET film, PVC film and other types of inserts).

Product description and advantages

Due to the good characters of EVA film in adhesion, durability,moisture resistance, it was more and more widely used in current components and a variety of optical products. such as partition wall and shower room.

The most important properties of the film include:

High durability

Protection against impact

Humidity resistance

Good adhesion to glass & variety kinds of inserts

Low water absorption rate

Storage condition:

It is usually stored in a ventilated, dry and clean warehouse, avoiding direct sunlight and radiation of heat, preventing moisture and heavy pressure. The temperature of the warehouse should ≤ 35℃, and the humidity ≤55%. It should not be placed directly on the ground, supported by wooden boards or other things to facilitate ventilation, heat dissipation and moisture isolation. If the film is pressurized, heated, and exposed to excessive moisture, it will cause different degrees of self-adhesion. If the surface humidity of the film is too high, it will also affect the bonding strength of the film and glass and other glass interlayer materials, affecting normal use. The film should be used as soon as possible after opening. If it is not applicable temporarily, the film should be sealed and packaged.

| Product | Specifications ( Thickness) | |

| High Clear EVA film | 0.25mm, 0.38mm | Max 2400mm |

| Ultra Clear EVA film | 0.25mm, 0.38mm, 0.50mm, 0.76mm, 1.52mm | Max 2600mm |

| White EVA film | 0.38mm * 2000mm/2400mm *100m | |

| Color EVA film | 0.38mm * 2000mm/2400mm *100m | |

Technical Data

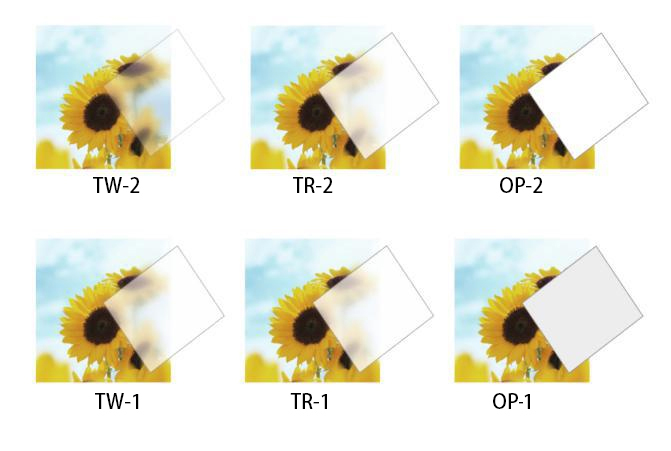

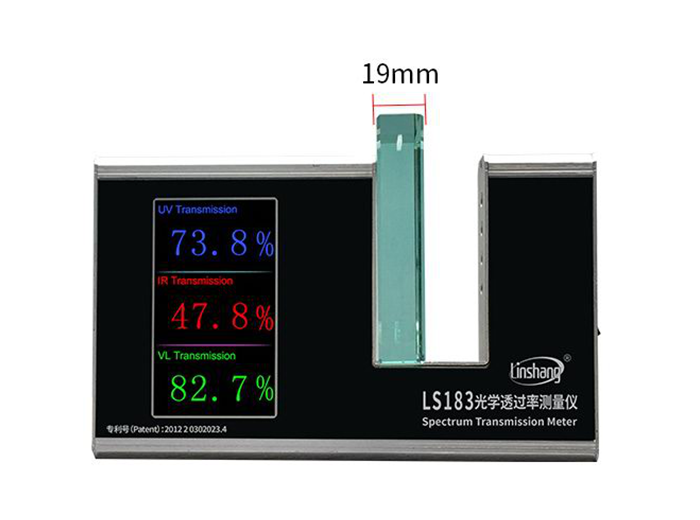

| Product | TW-2 | TW-1 | TR-2 | TR-1 | OP-1 | OP-2 |

| Transmittance % | 46 | 28 | 12 | 5 | 0.8 | 0.3 |

| Shodow Block % | 53 | 78 | 86 | 92 | 96 | 98 |

Product detail pictures:

Related Product Guide:

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for Newly Arrival Glass lamination process - White EVA film – Xiaoshi , The product will supply to all over the world, such as: Vancouver, Ukraine, Portugal, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.