Manufacturing Companies for Laminated Glass Metal Mesh - Silicon Vacuum Bag – Xiaoshi

Manufacturing Companies for Laminated Glass Metal Mesh - Silicon Vacuum Bag – Xiaoshi Detail:

Product Description

Silicon rubber sheet mainly used in the food industry, machinery industry, and other requirements, high temperature and shock resistance, various high pressure area.

The silicon rubber material Low and high temperature resistance rang are between -40℃~260℃. It has characters of Non-toxic, ozone-resistant, light-resistant, aging-resistant,High insulation.

High temperature resistant silicone sheet available Thickness are 0.2mm or 0.3mm. Maximum width 4000mm. Color available are blue,green and milky white.

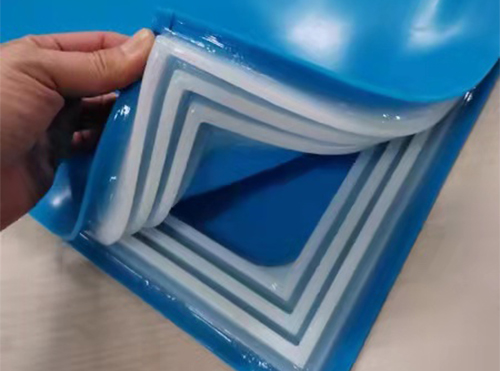

Silicon vacuum bag (made of silicon rubber sheet ) is a core part of glass vacuum laminated furnace, it makes up of two pieces of silicone rubber sheet and silicone sealing zipper edge, silicone rubber sheet is a key component of the entire laminated furnace, its quality directly affects the quality of glass lamination.

User Instruction

1. Before the silicone bag is used for the first time, please close it after heating and vacuum it, and check the vacuum degree and pressure holding condition according to the production process of laminated glass.

2. During layout process, the glass must be sealed with high temperature-resistant tape to prevent the laminated glass dislocation during vacuum process.

The collision and skew between them will cause the glass to be broken and scrapped, and it can also prevent the glue over flow in the vacuum process.

3.The corners of the glass must be protected if the lamination process was done before edge polishing. This will help prolong the life time of silicone bag.

4.If there are more than 3 layers of laminated glass lamination together, a 20cm-wide isolation cloth (high temperature resistant PET film or silicone sheet) should be placed close to the silicone bag around the upper and lower covers of the silicone bag, at the suction nozzles on both sides of the vacuum bag Cut out vents to prevent vacuum clogging.

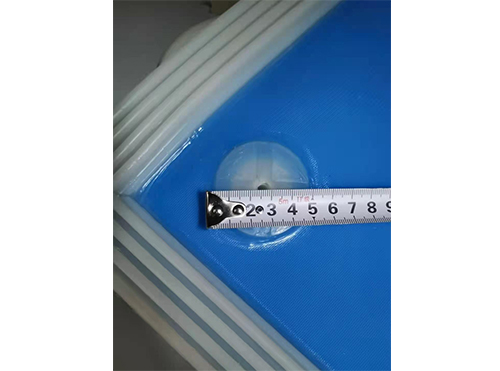

5.The suction nozzles on both sides of the vacuum bag must maintain gas circulation, A breathable Teflon mesh suggest to be used.

6. The silicon bag must keep the tightness of the upper and lower clasps to ensure the sealing of the vacuum bag, then turn on the vacuum pump, and observe the vacuum gauge under the operation of the vacuum pump. Generally, the pointer of the vacuum gauge is -0.08mp~-0.1mp. If it jumps back and forth or does not move in the original position, it is judged that the vacuum bag is ruptured or there are other air leakage positions. (Pay attention to observe whether the vacuum bag is pumped tightly!!!)

Product description and advantages

1.Anti-high and low temperature (-40℃~+260℃)

2. Flexible and soft surface.

3.UV-Resistance,Ozone Resistant.

4. Excellent Anti-slip performance

Product Specification

| Item | Silicon vacuum bag |

| Color | White, Blue, Green |

| Surface | Smooth or Textured |

| Max Width | 4000mm |

| Thickness | 2mm or 3mm |

| Insertion | Available |

| Density | 1.15-1.2 g /cm3 |

| Hardness | 55±5 Shore A |

| Elongation | 450 – 650% |

| Tensile strength | 6.5 – 8 Mpa |

| Tear resistance | 26 -32 N/mm |

| Temperature range | -40 ℃ - 260 ℃ |

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Manufacturing Companies for Laminated Glass Metal Mesh - Silicon Vacuum Bag – Xiaoshi , The product will supply to all over the world, such as: Kyrgyzstan, Croatia, Lithuania, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly