Low MOQ for Safety glass lamination - High transparent EVA – Xiaoshi

Low MOQ for Safety glass lamination - High transparent EVA – Xiaoshi Detail:

Product Description

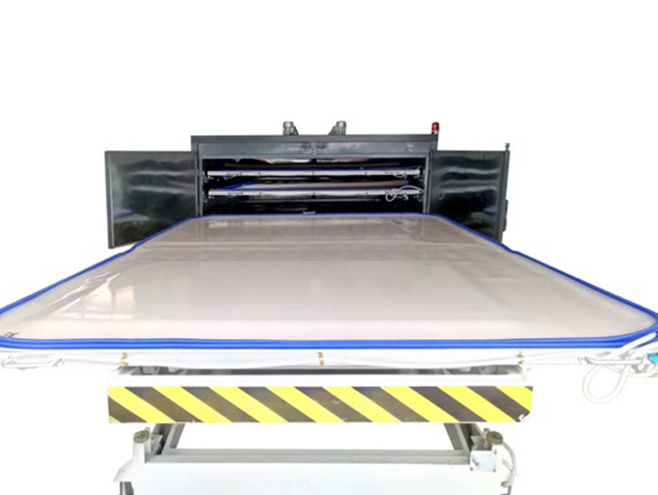

Laminated glass EVA film is placed between two layers of glass, a continuous vacuum is requested to pump out air when heated up to soften the film and laminate 2 pcs of glass into safety glass.

High transparent EVA film can be used for both indoor and outdoor transparent glass lamination and also insert materials lamination. It has lower lamination temperature which are suitable for match with different types of inserts( Fabric, PET film, PVC film and other types of inserts).

Product description and advantages

The EVA film has many features that make it an excellent material for creating laminates. Due to the good characters of EVA film in adhesion, durability,moisture resistance, it was more and more widely used in current components and a variety of optical products. such as construction wall,cover grid,shower room, show case, bank counter,Anti-smash glass and so on.

The most important properties of the film include:

High transparency and durability

Protection against impact

Humidity resistance

Good adhesion to glass & variety kinds of inserts

Low water absorption rate

Storage condition:

It is usually stored in a ventilated, dry and clean warehouse, avoiding direct sunlight and radiation of heat, preventing moisture and heavy pressure. The temperature of the warehouse should ≤ 35℃, and the humidity ≤55%. It should not be placed directly on the ground, supported by wooden boards or other things to facilitate ventilation, heat dissipation and moisture isolation. If the film is pressurized, heated, and exposed to excessive moisture, it will cause different degrees of self-adhesion. If the surface humidity of the film is too high, it will also affect the bonding strength of the film and glass and other glass interlayer materials, affecting normal use. The film should be used as soon as possible after opening. If it is not applicable temporarily, the film should be sealed and packaged.

Technical Data of High clear EVA film

| Item | Data |

| Melting Point | 68 ℃ |

| Density | 0.985 g/CM3 |

| Water Absorption | ≦ 0.1 % |

| Light Transmittance | > 85% |

| Haze | <0.2% |

| Tensile Strength | 21 Mpa |

| Elongation at Break | 542% |

| Cross Linking | 85% |

| UV Resistance(290-385nm) | 89.20% |

| Yellow Index(YI) | < 3.0 |

| UV Resistance(290-385nm) | 89.20% |

| Dumping & Heat Resistance (85 ℃, 85% RH) | 88.60% |

| Boiling Test (2 hrs into 100℃water) | Qualified |

| Product Name | Specification(Customized width available) | |

| High Clear EVA film | 0.25mm, 0.38mm | Max 2400mm |

| Ultra Clear EVA film | 0.38mm, 0.50mm, 0.76mm, 1.52mm | Max 2600mm |

| White EVA film | 0.38mm * 2000mm/2400mm *100m | |

| Color EVA film | 0.38mm * 2000mm/2400mm *100m | |

Product detail pictures:

Related Product Guide:

Our company sticks into the basic principle of Quality is definitely the life of the business, and status may be the soul of it for Low MOQ for Safety glass lamination - High transparent EVA – Xiaoshi , The product will supply to all over the world, such as: Estonia, Denver, Lebanon, We pursue the management tenet of Quality is superior, Service is supreme, Reputation is first, and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.