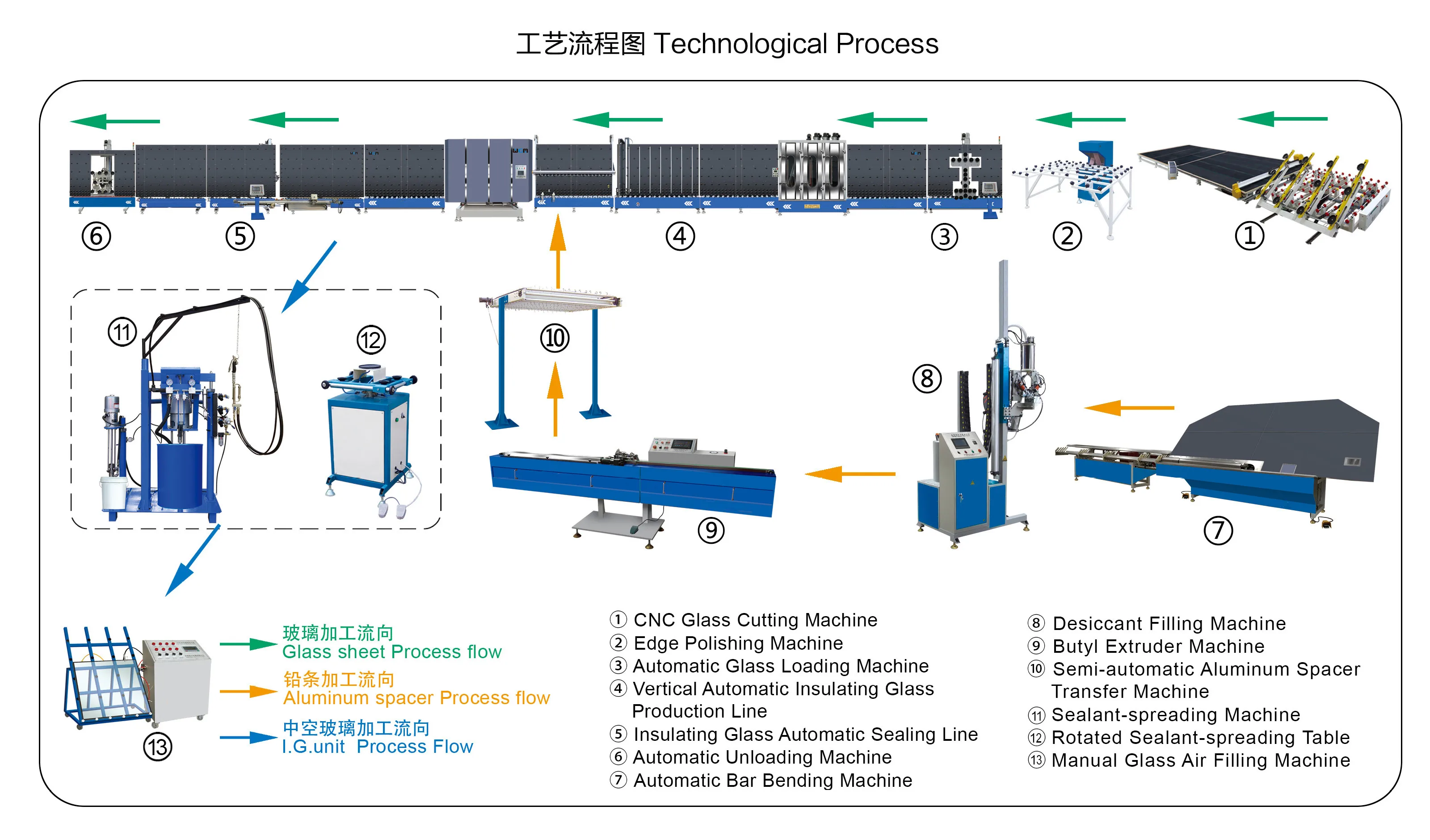

Insulating glass production line

Product Details Introduction

Product Details Introduction

Vertical Automatic Insulating Glass Production Line is a high-efficiency insulating glass processing equipment. This line can not only produce ordinary insulating glass but also for low-e insulating glass. It is a better mass production equipment to produce insulating glass with high automatic degree, high efficiency, easiness of operation and maintenance

Automatic numerical control insulated glass production line(LOW-E insulating glass can be produced).

Washing machine using 3 pairs of LOW-E special brush design and glass brush to avoid membrane damage.

Can produce over two layers and three layers,size(equilateral) hollow glass curtain wall and special-shaped hollow glass. Full range automatic frequency control,with the glass waiting storage section,save labor waiting time,improve production efficiency. Board press hydraulic control,servo motor to adjust up and down the size of the plate,the

movable plate can be free to open,convenient and quick maintenance. Glass films flat press and box mechanical hand lever type material support,mechanical hard limit + activity in sucking) ensure automatic glass films never dislocation.

The cleaning box,air drying box,air knife and other all stainless steel production, beautiful appearance,never rust.

Equipment Features:

Double-beam system reduces the contact between glass and backrest wheel, and achieves the high-quality requirement of

no trace on the surface of hollow glass.

- Full PLC control system, touch screen man-machine interface.

- Can clean online and online LOW-E glass.

- The speed of cleaning LOW-E glass brush can be driven by frequency conversion.

- The air knife of the cleaning machine can be automatically adjusted according to the glass thickness.

- Digital control production line, intermittent work energy-saving system.

- Servo plate pressing, accurate tablet pressing, with functions of inflation, lm closing and tablet pressing.

- Automatic detection of glass size, automatic adjustment of the best inflation time, inflation rate of more than 90%, saving gas

consumption.

Technical Data:

| Type | SG2000 | SG2500 | SG2700 | SG2800 | SG3000 | SG3300 |

| Input Voltage | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Total power | ≈22kW | ≈28kW | ≈48kW | ≈50kW | ≈68kW | ≈76kW |

| Min. glass size | 300×300mm | 300×300mm | 300×300mm | 300×300mm | 300×300mm | 300×300mm |

| Max. glass size | 2000×3000mm | 2500×4000mm | 2700×5000mm | 2800×5000mm | 3000×6000mm | 3300×7000mm |

| Max I.G. unit thickness | < 50mm | < 50mm | < 80mm | < 80mm | < 80mm | < 80mm |

| Inflating time | 2~10s | 2~10s | 2~10s | 2~10s | 2~10s | 2~10s |

| Transmission speed | 0~45m/min | 0~45m/min | 0~45m/min | 0~45m/min | 0~45m/min | 0~45m/min |

| Glass cleaning speed | 2~10m/min | 2~10m/min | 2~10m/min | 2~10m/min | 2~10m/min | 2~10m/min |

| Glass cleaning thickness | 3~19mm | 3~19mm | 3~28mm | 3~28mm | 3~28mm | 3~28mm |

| Overall dimension | 19500×2800×3100mm | 25100×2800×3450mm | 28100×2800×3450mm | 33100×2800×3450mm | 39500×3200×4050mm | 48500×3200×4050mm |