Hot Sale for Pvb Film Glass - Solar EVA film – Xiaoshi

Hot Sale for Pvb Film Glass - Solar EVA film – Xiaoshi Detail:

Solar EVA film

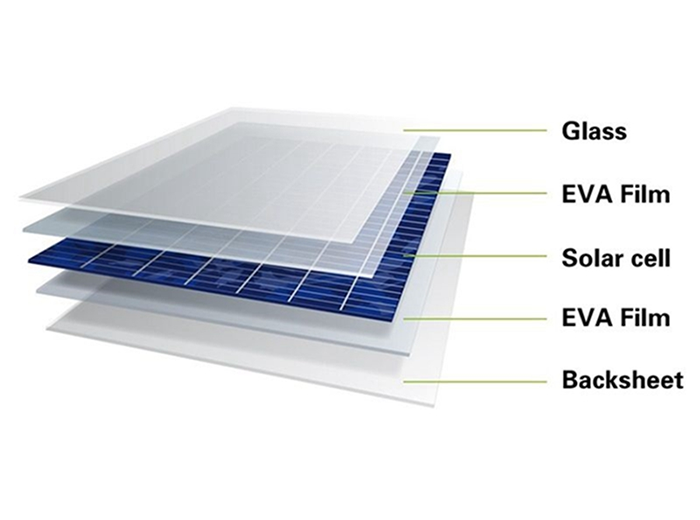

In the solar PV module production industry, the most common encapsulation material is EVA film. With the help of a lamination machine, the solar cells are laminated between the Eva solar films in a vacuum, which is under compression. Once the solar EVA sheets have been laminated, the EVA film play an important role in preventing humidity to ensure the Solar Panel efficiency . High quality solar EVA film will definitely prolong the life span of solar panel.

EVA solar film play an important part in enhancing the durability and performance of solar panels. They enable the solar cells to ‘float’ between the glass and the backsheet, helping to soften shocks and vibrations and protecting the cells and their circuits. High-performance EVA sheets we supply are subject to rigorous quality testing and verification. Featuring products in a wide range of sizes and types, our portfolio of EVA films is a trusted source for many of the world’s largest photovoltaic module manufacturers.

Product description and advantages

• Excellent durability & Weather resistance

• High-temperature& humidity resistance

• UV light resistance

• Excellent adhesion to glass & PET,ETFE,TPT

• Excellent light transmittance and transparency

• High cross-linking rate after lamination

Storage condition and life time

- 1.T≤30°C,H≤70%

- 2.Shift time is 8-12 months

- 3.All open carton EVA film must be used up within 24hours and avoid it absorb some dust and water

Technical Data

| Product | Solar EVA flm | ||

| Performance | Unit | High Transparent | |

| Tensile Strength | mpa | >15 | |

| Elongation at Break | % | 500 | |

| Peel Strength with Glass | N/cm | >80 | |

| (140℃ 15mins curing) | |||

| Peel Strength with Backsheet | N/cm | >60 | |

| (140℃ 15mins curing) | |||

| Transmittance | 280-380nm | % | ≥80 |

| (after curing) | 238-800nm | % | ≥91 |

| Volume Resistance | Ω·cm | ≥1×1015 | |

| Shrinkage Rate | % | MD<3 | |

| (120℃, 5mins before curing) | TD<1.5 | ||

| Complete Cross-linking Degree | % | >75 | |

| (140℃, 15mins) | |||

| UV/Aging Resistance | △YI | <5 | |

| (UV, 1000hrs) | |||

| Wet Heat Ageing | △YI | <5 | |

| (+85℃,85% humidity,1000hrs) | |||

Product specification

| Thickness : | 0.35mm~0.6mm (tolerance: -0.03~+0.1mm) |

| Maximum width: | 1600mm |

| Roll length: | 100m/200m or customized. |

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for Hot Sale for Pvb Film Glass - Solar EVA film – Xiaoshi , The product will supply to all over the world, such as: Ghana, Jakarta, Indonesia, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Managers are visionary, they have the idea of mutual benefits, continuous improvement and innovation, we have a pleasant conversation and Cooperation.