2022 High quality Insulating glass material - PET Vacuum film – Xiaoshi

2022 High quality Insulating glass material - PET Vacuum film – Xiaoshi Detail:

Introduce of High temperature vacuum film

Laminated glass high temperature vacuum film is a kind of composite plastic film/bag which can be heated and vacuum-pumped. The sealing performance after vacuum-pumping is excellent.

PET film is a relatively comprehensive film. It has good transparency and gloss; it has good air tightness and moisture resistance. PET film has excellent mechanical properties, its toughness is the best among all thermoplastics, and its tensile strength and impact strength are much higher than ordinary films. PET film also has excellent heat and cold resistance and good chemical and oil resistance.In addition to the excellent physical and mechanical properties of ordinary polyester films, the PET film also has excellent optical properties, such as good transparency, low haze and high gloss.

Ordinary PET is a crystalline polymer. After the PET film is stretched and oriented, it will produce a large degree of crystallization. If it is heat-sealed, it will shrink and deform, so the ordinary PET film does not have heat-sealing properties.

In order to solve the problem of heat sealing, through the modification of PET resin and the use of A/B/C three-layer structure die, a three-layer co-extruded heat-sealing PET film has been developed. This heat-sealing PET film One side is a heat-seal-able layer, so it can be directly heat-sealed, which is very convenient to use.

Features:

Strong air barrier performance

Anti-oxidation

Water-proof

Strong moisture-proof mechanical properties

High explosion resistance

Puncture resistance and tear resistance

High temperature resistance (160 ℃) and low temperature resistance (-50 ℃)

Non-toxic, compliance with good transparency

Application Area:

Laminated bending/tempered glass to meet the high quality demand of modern buildings and automobiles, including SGP/PVB and EVA silk-clamping glass.

Standard size

|

Item |

T(mm) * W(mm) * L(M) |

SQM / Roll |

|

1 |

0.09 *1670 *250 |

417.5 |

|

2 |

0.09 *2100 *250 |

530 |

|

3 |

0.09 *2300 *250 |

580 |

|

4 |

0.09 *2500 *250 |

625 |

|

5 |

0.09 *2700 *250 |

675 |

|

6 |

0.09 *3000 *200 |

600 |

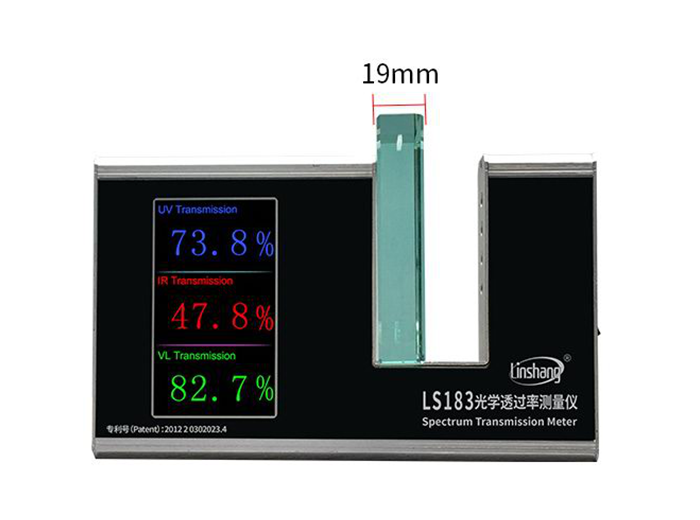

Technical Data

|

Item |

Methods |

Results |

Unit |

|

Thickness |

// |

≥ 0.1 ± 10% |

mm |

|

Tensile strength |

ASTM D 882 |

≥MD:150 ≥TD:140 |

N |

|

Puncture resistance |

FTMS 101 Method 2065 |

20Ibs |

IBS |

|

Seal strength |

ASTM D 882 |

100N |

N/25mm |

|

Sealing temperature |

// |

170℃ – 210℃ |

℃ |

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of Quality is the life of your company, and status will be the soul of it for 2022 High quality Insulating glass material - PET Vacuum film – Xiaoshi , The product will supply to all over the world, such as: United States, Tanzania, Albania, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.